| 基 本 尺 寸(mm) | 基本额定载荷(kN) | 轴 承 代 号 | ||||||||

| Boundary Dimensions | Basie Load Ratings | |||||||||

| Bearing Numbers | ||||||||||

| d | D | T | B | r1.3min | r3.5min | Cr | Cor | |||

| 152.4 | 244.475 | 187.325 | 192.088 | 1 | 3.3 | 1300 | 2160 | 152TQOS244-1 | ||

| 203.2 | 317.5 | 266.7 | 266.7 | 2.5 | 3.3 | 2460 | 4900 | 203TQOS317-1 | ||

| 206.375 | 282.575 | 226 | 226 | 0.6 | 3.3 | 1300 | 3350 | 206TQOS282-1 | ||

| 220.662 | 314.325 | 239.712 | 239.712 | 1.5 | 3.3 | 1790 | 3800 | 220TQOS314-1 | ||

| 228.6 | 400.05 | 296.875 | 296.875 | 2.5 | 3.3 | 3360 | 5700 | 228TQOS400-1 | ||

| 241.478 | 349.148 | 228.6 | 228.6 | 1.5 | 3.3 | 1900 | 3650 | 241TQOS349-1 | ||

| 254 | 358.775 | 269.875 | 269.875 | 1.5 | 3.3 | 2330 | 5400 | 254TQOS358-1 | ||

| 260 | 365 | 340 | 340 | 2.5 | 3.5 | 3140 | 8000 | 260TQOS365-1 | ||

| 266.7 | 355.6 | 228.6 | 230.188 | 1.5 | 3.3 | 1720 | 4150 | 266TQOS355-1 | ||

| 276.225 | 393.7 | 269.875 | 269.875 | 1 | 6.4 | 2750 | 5850 | 276TQOS393-1 | ||

| 280 | 395 | 340 | 340 | 2.5 | 3.5 | 3580 | 8650 | 280TQOS395-1 | ||

| 285.75 | 380.898 | 244.475 | 244.475 | 1 | 3.3 | 2200 | 5500 | 285TQOS380-1 | ||

| 300 | 440 | 279.4 | 280.99 | 3.3 | 4.8 | 3080 | 6700 | 300TQOS440-1 | ||

| 304.648 | 438.048 | 279.4 | 280.99 | 2 | 4.8 | 3080 | 6700 | 304TQOS438-1 | ||

| 304.8 | 419.1 | 269.875 | 269.875 | 1 | 6.4 | 2860 | 6950 | 304TQOS419-1 | ||

| 501.65 | 336.55 | 336.55 | 2 | 6.4 | 4730 | 9300 | 304TQOS501-1 | |||

| 304.902 | 412.648 | 266.7 | 266.7 | 1 | 3.3 | 2700 | 6700 | 304TQOS412-1 | ||

| 305 | 438.048 | 279.4 | 280.99 | 2 | 4.8 | 3080 | 6700 | 305TQOS438-1 | ||

| 317.5 | 422.275 | 269.875 | 269.875 | 1.5 | 3.3 | 2640 | 6550 | 317TQOS422-1 | ||

| 333.375 | 469.9 | 342.9 | 342.9 | 2.5 | 3.3 | 4290 | 10400 | 333TQOS469-1 | ||

| 343.052 | 457.098 | 254 | 254 | 1 | 3.3 | 2330 | 6000 | 343TQOS457-1 | ||

| 355.6 | 482.6 | 269.875 | 265.112 | 1.5 | 3.3 | 3080 | 7500 | 355TQOS482-1 | ||

| 488.95 | 317.5 | 317.5 | 1 | 3.3 | 4130 | 10000 | 355TQOS488-1 | |||

| 385.762 | 514.35 | 317.5 | 317.5 | 1 | 3.3 | 3910 | 10000 | 385TQOS514-1 | ||

| 406.4 | 546.1 | 288.925 | 288.925 | 1.5 | 6.4 | 3910 | 9500 | 406TQOS546-1 | ||

| 546.1 | 330 | 330 | 1.5 | 6.4 | 4020 | 10200 | 406TQOS546-2 | |||

| 409.575 | 546.1 | 334.962 | 334.962 | 1 | 6.4 | 4570 | 12000 | 409TQOS546-1 | ||

| 415.925 | 590.55 | 434.975 | 434.975 | 3.3 | 6.4 | 7040 | 18000 | 415TQOS590-1 | ||

| 416 | 574 | 440 | 440 | 2.5 | 5 | 6050 | 17000 | 416TQOS574-1 | ||

| 430 | 575 | 380 | 380 | 1.5 | 5 | 5230 | 14300 | 430TQOS575-1 | ||

| 440 | 590 | 480 | 480 | 1 | 5 | 7040 | 19200 | 440TQOS590-1 | ||

| 650 | 353.5 | 353.5 | 5.5 | 6.4 | 6160 | 13200 | 440TQOS650-1 | |||

| 450 | 595 | 398 | 398 | 2 | 6 | 5500 | 16300 | 450TQOS595-1 | ||

| 457.2 | 596.9 | 279.4 | 276.225 | 1.5 | 3.3 | 3960 | 10000 | 457TQOS596-1 | ||

| 460 | 610 | 360 | 360 | 3 | 6 | 5120 | 12900 | 460TQOS610-1 | ||

| 475 | 600 | 368 | 368 | 2 | 6 | 4730 | 14000 | 475TQOS600-1 | ||

| 479.425 | 679.45 | 495.3 | 495.3 | 3.3 | 6.4 | 8580 | 2240 | 479TQOS679-1 | ||

| 482.6 | 615.95 | 330.2 | 330.2 | 1 | 6.4 | 4950 | 13700 | 482TQOS615-1 | ||

| 615.95 | 402.05 | 402.05 | 1 | 6.4 | 5610 | 17300 | 482TQOS615-2 | |||

| 482.6 | 630 | 420 | 420 | 3.3 | 6.4 | 5940 | 17000 | 482TQOS630-1 | ||

| 489.026 | 634.873 | 320.675 | 320.675 | 1 | 3.3 | 4840 | 12500 | 489TQOS634-1 | ||

| 510 | 655 | 379 | 377 | 1.5 | 6.4 | 5720 | 16300 | 510TQOS655-1 | ||

| 540 | 690 | 434 | 434 | 2 | 5 | 7040 | 21200 | 540TQOS690-1 | ||

| 558.8 | 736.6 | 322.262 | 322.262 | 1.5 | 6.4 | 5830 | 14300 | 558TQOS736-1 | ||

| 736.6 | 409.575 | 409.575 | 3.3 | 6.4 | 6600 | 20000 | 558TQOS736-2 | |||

| 736.6 | 457.2 | 455.612 | 3.3 | 6.4 | 7920 | 23200 | 558TQOS736-3 | |||

| 571.5 | 812.8 | 593.725 | 593.725 | 3.3 | 6.4 | 11900 | 33500 | 571TQOS812-1 | ||

| 585.788 | 771.525 | 479.425 | 479.425 | 4 | 6.4 | 9520 | 27500 | 585TQOS771-1 | ||

| 609.6 | 787.4 | 361.95 | 361.95 | 3.3 | 6.4 | 6820 | 18600 | 609TQOS787-1 | ||

| 813.562 | 479.425 | 479.425 | 3.3 | 6.4 | 9680 | 27500 | 609TQOS813-1 | |||

| 635 | 901.7 | 654.05 | 654.05 | 3.3 | 6.4 | 14500 | 41500 | 635TQOS901-1 | ||

| 679.45 | 901.7 | 552.45 | 552.45 | 3.3 | 6.4 | 12100 | 36000 | 679TQOS901-1 | ||

| 682.625 | 965.2 | 701.675 | 701.675 | 3.3 | 6.4 | 17200 | 49000 | 682TQOS965-1 | ||

| 685.8 | 876.3 | 355.6 | 352.425 | 3.3 | 6.4 | 7210 | 20000 | 685TQOS876-1 | ||

| 710 | 900 | 410 | 410 | 3 | 6 | 8250 | 24000 | 710TQOS900-1 | ||

| 711.2 | 914.4 | 317.5 | 317.5 | 2.5 | 6.4 | 6600 | 17300 | 711TQOS914-1 | ||

| 749.3 | 990.6 | 605 | 605 | 3.3 | 6.4 | 13200 | 40500 | 749TQOS990-1 | ||

| 762 | 1079.5 | 787.4 | 784.4 | 4.8 | 12.7 | 21200 | 61000 | 762TQOS1079-1 | ||

| 825.5 | 1168.4 | 844.55 | 844.55 | 4.8 | 12.7 | 24600 | 73500 | 825TQOS1168-1 | ||

| 863.6 | 1169.987 | 844.55 | 844.55 | 4.8 | 12.7 | 23300 | 71000 | 863TQOS1169-1 | ||

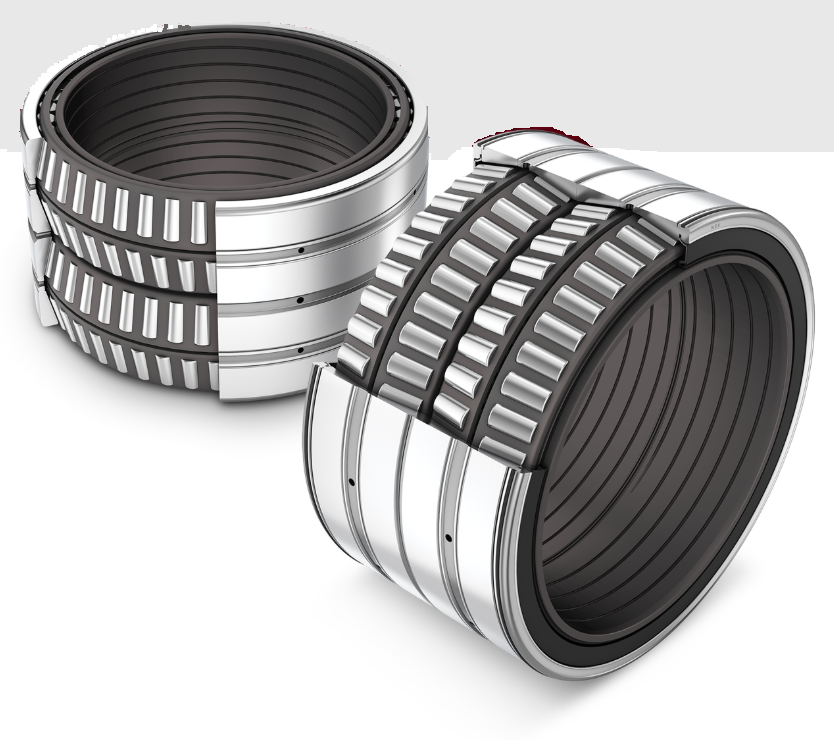

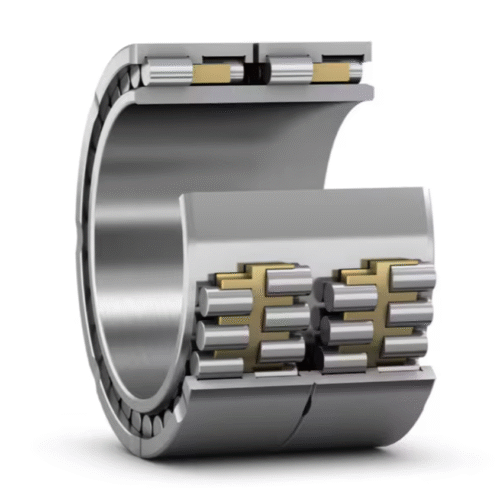

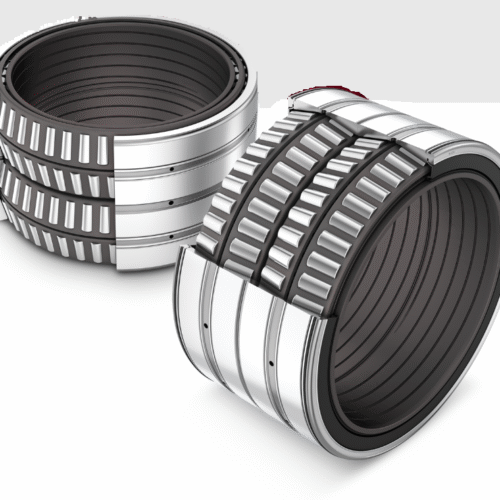

Four Row Tapered Roller Bearing with seals

Four-row tapered roller bearings

Used in bearing configurations of rolling mills worldwide at low to medium speeds.

The four-row tapered roller bearing is a specially designed angular contact bearing. Its multi-row roller arrangement can simultaneously withstand high radial loads and some axial loads. The bearing’s inner diameter has a loose fit design with the roll neck for easy installation and disassembly, but spiral oil grooves are needed to prevent slip creep. It is mainly used in four-high hot rolling mills, work rolls of cold rolling mills, and billet mills, and its compact design can replace additional thrust bearings.

The four-row tapered roller bearing uses a multi-row staggered arrangement of tapered rollers, significantly increasing load-bearing capacity by increasing the number of roller rows. Its inner ring has a loose fit with the roll neck for quick installation and disassembly, but spiral oil grooves are often machined into the inner diameter to improve lubrication and prevent slip creep caused by the clearance.

Functional characteristics:

This bearing can simultaneously withstand radial forces and some axial forces generated during rolling, eliminating the need for additional thrust bearings and making the rolling mill structure more compact.

Application Scenarios: Primarily used in rolling mill bearing configurations to withstand radial and axial loads, eliminating the need for additional thrust bearings and resulting in a more compact main machine structure:

1. Work roll support for four-high hot and cold rolling mills

2. Roll configuration for steel beam rolling mills and billet mills

3. Bearing systems for low- to medium-speed rolling mills

Comparative Advantages: Compared to similar six-row cylindrical roller bearings,

four-row tapered roller bearings have a lower coefficient of friction and higher axial load capacity,

but a slightly lower radial load capacity.